Implants

Implants

Loupes

Regeneration

Drills and screws

Surgery

Periodontology

Endodontics

With a long-term view of clinical success, our product development is driven by science, not trends.

We deliver a single, comprehensive implant system, based on a unique, proven design –

the MULTIGUARD Protection Solution – that we’ve optimized over three decades of clinical success.

A combination of innovative features working together to protect implant integrity

by maintaining mechanical stability and an optimal bio-response for the life of the patient.

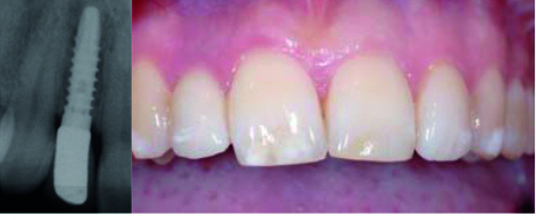

prof. M. Hürzeler, dr K. Meyenberg, dr U. Grunder

For optimal hard tissue response.

Faster osseointegration is promoted by the implant surface INICELL® which is the superhydrophilic state of the proven sandblasted and thermal acid-etched implant surface.

Designed for long-term mechanical stability.

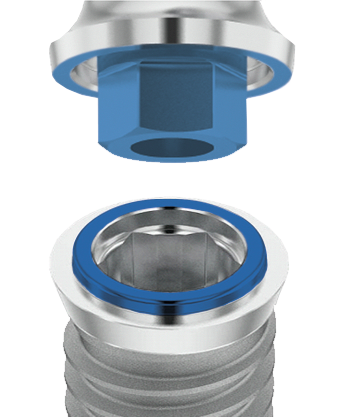

The EVERGUARD® Connection with an internal hex and external stabilization ring, ensures optimal long-term mechanical stability of the implant abutment connection.

For optimal soft tissue response.

The TISSUEGUARD® Collar encourages soft tissue adaptation to prevent bone loss and allows for surgical flexibility if needed.

We produce all Thommen implants from coldworked cp Titanium Grade 4. This material combines mechanical strength with excellent biocompatibility. INICELL ® is the conditioned state of the sandblasted and thermal acid-etched Thommen implant surface. Conditioning occurs immediately before implantation through contact with the conditioning solution. The result of this process is increased surface energy and improved wettability due to superhydrophilic properties, without any change of the clinically proven microroughness of the Thommen implant surface.

The INICELL® surface, which is immediately bioavailable, supports and accelerates the physiological processes during wound healing and early osseointegration.

1. Push in the cartridge

2. Shake the applicator five times

3. Place the implant

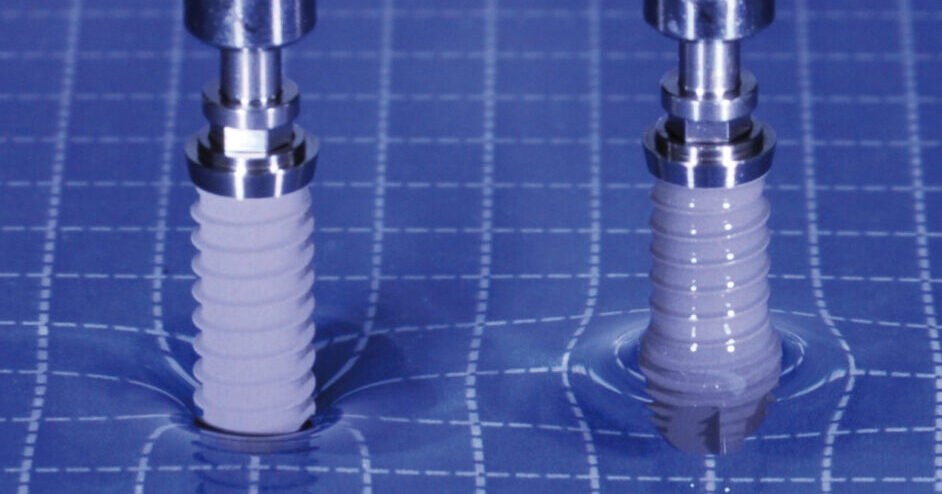

Wetting experiment with an ELEMENT implant with unconditioned surface (left) and INICELL® (right).

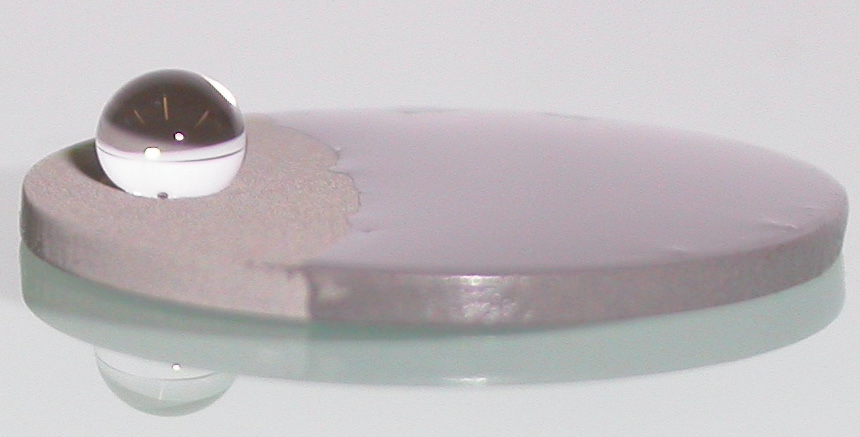

Sandblasted and thermal acid-etched model substrate with water on the unconditioned (left) and conditioned INICELL® (right) surface.

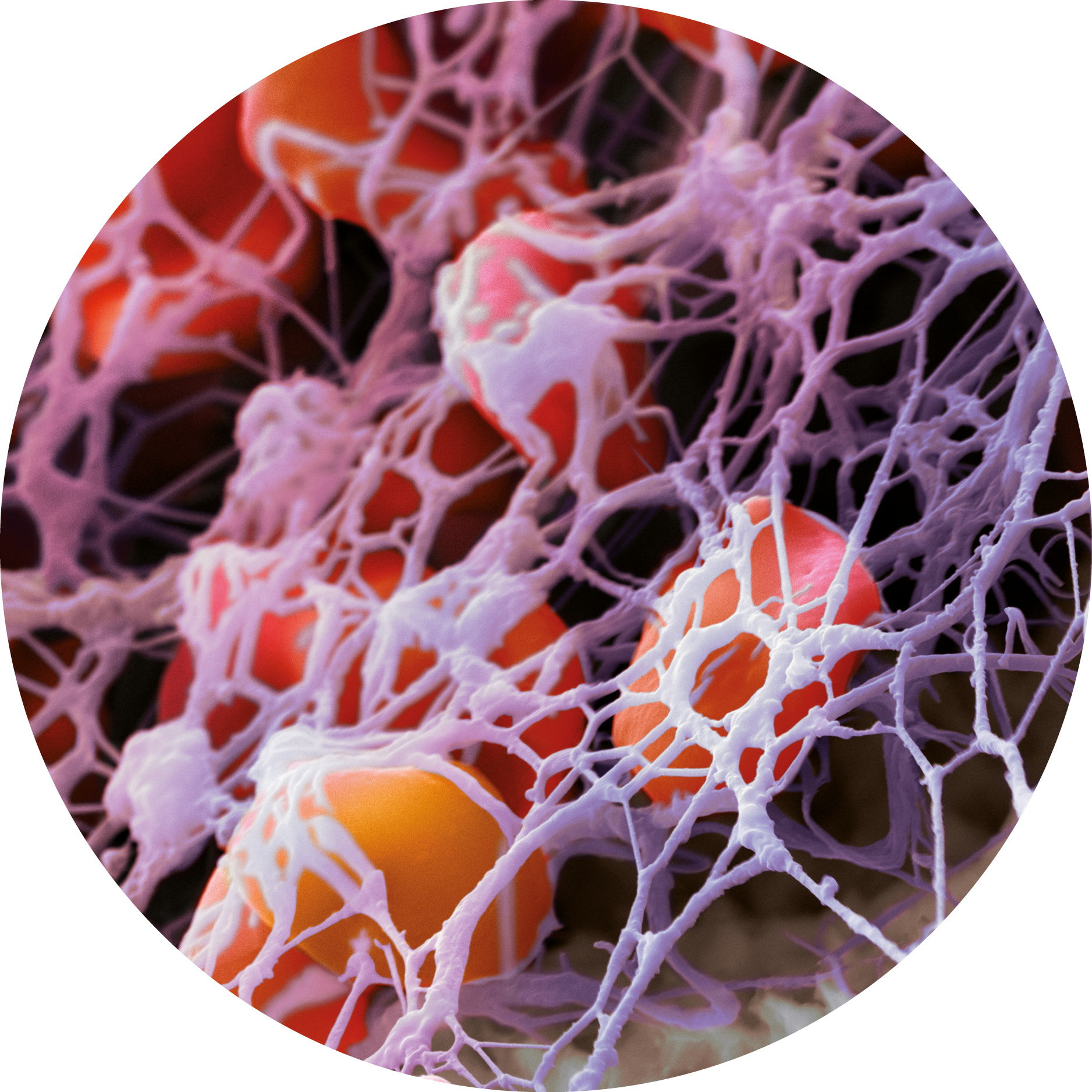

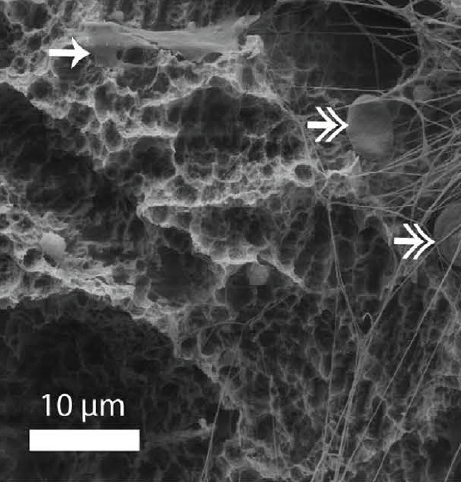

INICELL® enhances blood clot formation on the implant surface.

Unconditioned surface.

INICELL® enhances blood clot formation on the implant surface.

INICELL®.

It is the link between the implant which is anchored in bone and the prosthetic restoration. The implant abutment connection must enable aesthetically pleasing prosthetic restoration and maintenance must be worry free.

The internal hexagon of the EVERGUARD® Connection is manufactured with the highest precision and allows an extremely accurate transfer of the implant position to the master model, which in turn ensures a perfect fit for the prosthesis. The internal hexagon also provides precise rotational orientation and stability for single-tooth implant restorations thanks to the large, indexed contact surfaces.

A unique feature of the EVERGUARD ® Connection is the stabilization ring on the implant platform. This stabilization ring self-centers the abutment on the implant and carries the bulk of lateral chewing forces. It gives optimal mechanical stability to the implant abutment connection and minimizes micro-movements at the implant abutment EVERGUARD® Connection Designed for long-term mechanical stability The EVERGUARD ® Connection is designed for long-term mechanical stability and has proven itself through more than 35 years of clinical practice. With an internal hex and external stabilization ring, the EVERGUARD ® Connection ensures optimal long-term mechanical stability of the implant abutment connection. interface close to the bone and soft tissue.

Additionally, the stabilization ring focuses the contact area between the implant and abutment so that there is higher surface compression in the critical perimeter area of the connection with comparatively modest torque used on the abutment screw.

This minimizes the micro gap between the implant and abutment which reduces the occurrence of bacterial contamination.

Axial discrepancies, which can occur with conical connections are avoided and a perfect passive fit can be achieved even for complex multi-unit screw-retained restorations. In addition, the axial stop of the EVERGUARD® Connection eliminates the wedge effect observed with conical connection caused by the abutment sinking. This wedge effect reduces the preload of the abutment screw, which leads to screw loosening.

This wedge effect reduces the preload of the abutment screw, which leads to screw loosening.

To compensate for the preload loss caused by the wedge effect in actual clinical practice, the appropriate torque must be applied regularly and repeatedly after the functioning of the implant prosthesis.

The axial stop of the EVERGUARD® Connection preserves the abutment screwʼs preload.

The small screw head is possible because it does not need to withstand the higher clamping forces which other designs may require and it is protected from lateral loads by the stabilization ring.

The small screw head allows abutments to be produced with a narrower screw channel and thicker walls. This in turn gives the dental technician more freedom for prosthetic design and fabrication for a strong and esthetic result.

Due to the collar, the implant-abutment connection lies in most cases in the soft tissue, which results in an optimal healing situation for both, the soft tissue and the underlying bone. It also allows for easier impression taking and inserting or replacing the prosthesis.

The machined surface of the collar is optimal for soft tissue and is cleansable, which improves hygienic maintenance to reduce the risk of biologic complications including peri-implantitis.

It is of great benefit over the entire life of the implant that the prosthetic platform is within the soft tissue since the collar and the adjacent soft tissue form a safety zone above the bone.

Dr. Ueli Grunder, Zurich-Zollikon

2003

2013